Five Colour Options

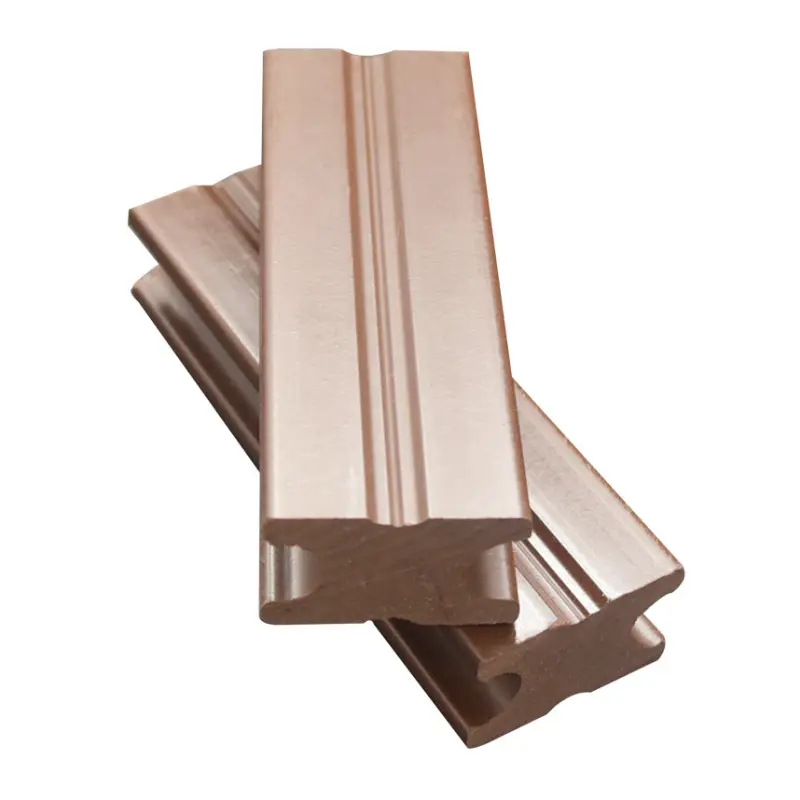

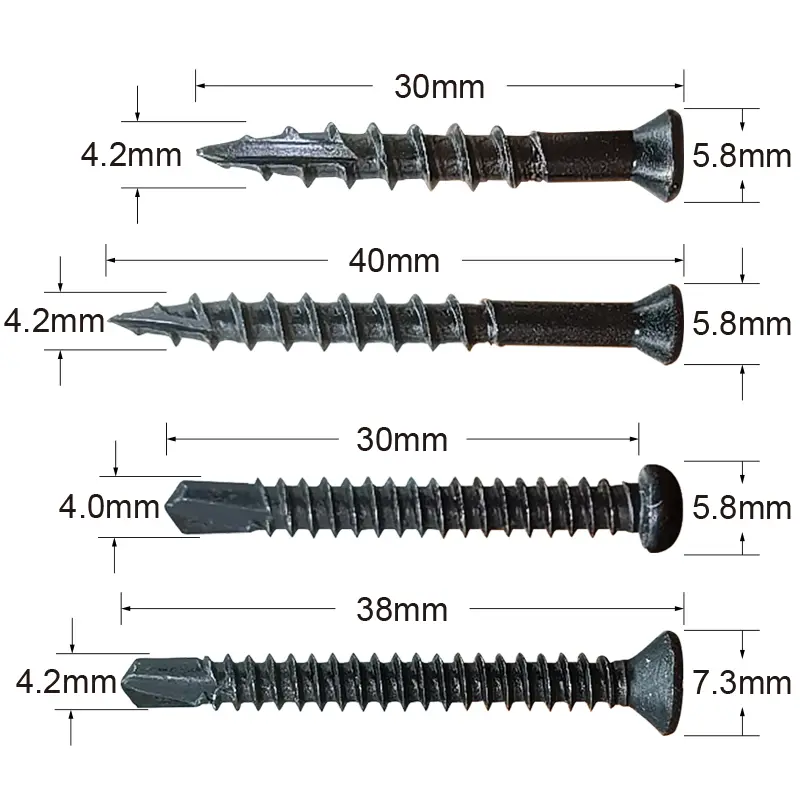

Wood plastic composite decking floor is the most commonly used material in home design and park pavement decoration. The later service life of WPC decking floor is affected by two factors: one is the quality of WPC decking floor, the other is the installation method of it.

Contact Us

>

Which composite deck board is right for you?

Take your pick from Tercel range of five composite deck boards, of which come in the six most popular colours (grey, teak, chocolate, charcoal and antique). Choose the affordable hollow Essential range, our traditional solid composite Classic range, or upgrade to our second-generation composite decking planks: the hollow capped composite Advanced range or the solid capped Deluxe range composite decking board.

All of our composite decking boards are more durable and longer-lasting than traditional wood. It’s all low maintenance – with no need for painting or staining. Made from an advanced formula of wood fibres and plastic, it looks and feels natural underfoot, but unlike wood, Tercel composite decking boards are resistant to costly problems such as warpage, mould, insect damage and rot.